Effects of Heat and Ultra-Sonic Processing on Some Qualities of Ma-Kiang (Cleistocalyx nervosum var. paniala) Juice

Keywords:

Ma-Kiang juice , ultra-sonic processing , bioactive compounds , food safetyAbstract

Background and Objectives : Cleistocalyx nervosum var. paniala, commonly known as “Ma-Kiang” in Thailand, belongs to the family Myrtaceae. This plant is a small to medium-sized tree found in tropical and subtropical regions, particularly in Southeast Asia. It has gained attention for its edible fruits and bioactive compounds, which are associated with various health benefits. Its fruits and extracts hold promise in health applications, particularly as natural antioxidants and anti-inflammatory agents. Ultra-sonic processing involves the use of high-frequency sound waves (20 kHz to several MHz) to generate intense pressure waves within a liquid medium. This technique has found significant applications in food processing, including fruit juice production, due to its ability to improve extraction, enhance flavor, and promote better preservation. The intense shear forces and heat generated during ultrasonication can also inactivate microorganisms (bacteria, yeasts, and molds) in fruit juices, improving the microbiological quality and extending shelf life. This, however, depends on the intensity, duration, and frequency of the ultrasound treatment. Ultra-sonic processing is considered another option for fruit juice processing, as it is a novel technology that can better preserve the bioactive compounds and antioxidant efficiency of the juice compared to heat processing. Therefore, this research aimed to investigate the effects of ultra-sonic processing on various qualities of Ma-Kiang juice compared to heat processing.

Methodology : To prepare Ma-Kiang juice, fresh Ma-Kiang fruits were harvested, washed and drained before refrigeration at 6ºC for 2 h before processing. The extraction of Ma-Kiang juice was done by extracting the Ma-Kiang fruits using a juicer extractor. Total soluble solids of the extracted juice were adjusted to 16ºBrix with fructose. Ma-Kiang juice was processed using a High Intensity Ultra-Sonic Processor with a frequency of 25 kHz and 20–80% amplitude for 30 min and heated at 80ºC for 2 min, then immediately cool it by immersing it in an ice-water bath for 5 min. All processed samples were stored at 4ºC prior to analyzing their qualities. Physico-chemical qualities of the treated samples including color parameter, viz. L (brightness), a* (redness/greenness), b*(yellowness/blueness), C* (chroma) and total different colors (∆E), viscosity, total soluble solids, pH and total titratable acidity (TTA) were investigated. To study the health benefits, total anthocyanin content, total phenolic compounds, and antioxidant capacity, viz. 2,2-diphenyl-1-picrylhydrazyl (DPPH) radical-scavenging activity, ferric-reducing antioxidant power (FRAP), and 2,2’-Azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) (ABTS+) radical scavenging activity were also assessed. Polyphenol oxidase (PPO) and peroxidase (POD) activities in the samples were monitored, and the residual of both enzymes were then calculated. According to the Thai Community Product Standard for Ma-Kiang juice (TCPS. 484/2014), some indicator microorganisms, viz. total plate counts, yeasts and molds, coliform bacteria, Escherichia coli, Salmonella, Staphylococcus aureus, Bacillus cereus and Clostridium perfringens, were determined.

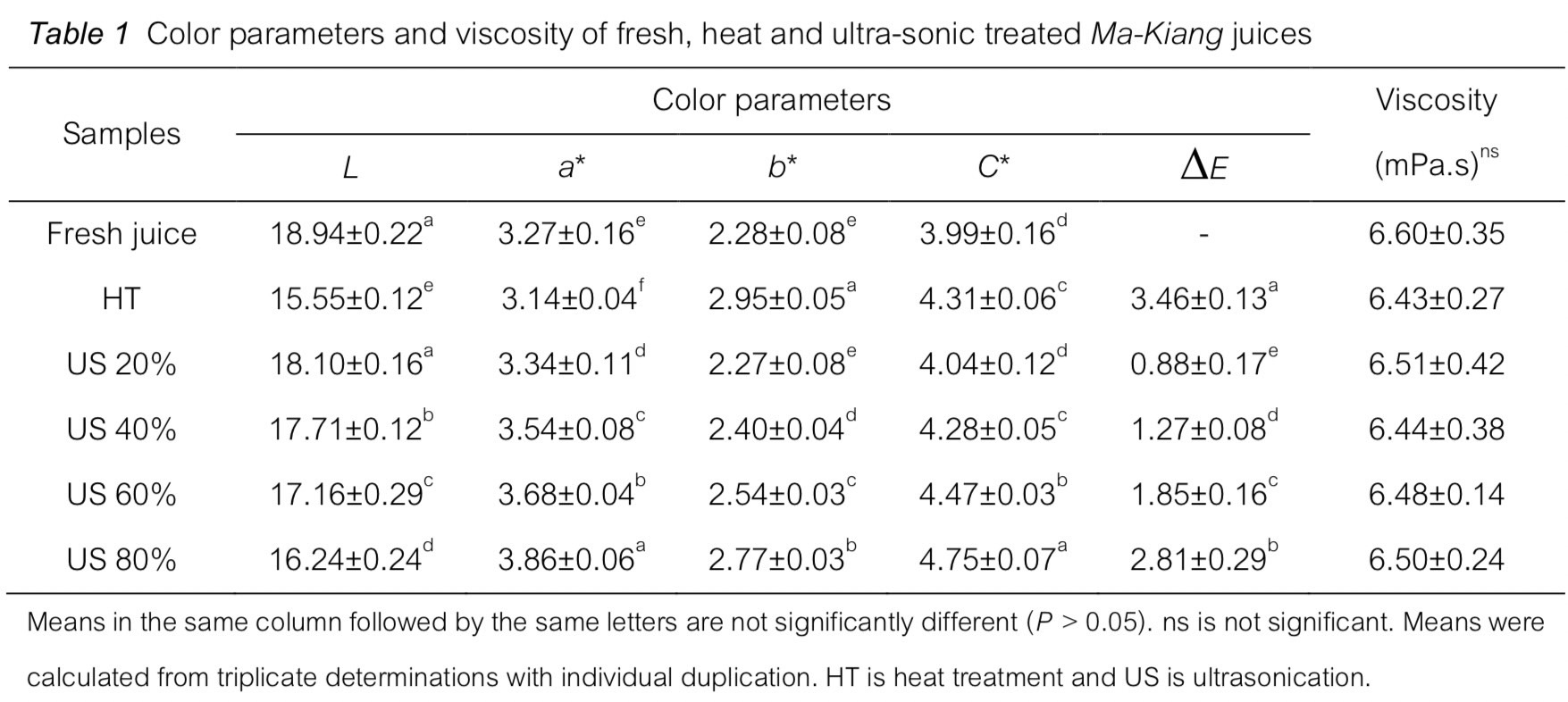

Main Results : From the experimental results, it was found that the brightness value (L) of the processed Ma-Kiang juice decreased after being treated with heat and high-frequency sound waves compared to fresh Ma-Kiang juice (control). It was noticed that when the intensity levels of the ultrasonic frequency increased, the L values of the samples significantly decreased. The heated Ma-Kiang juice had the lowest redness (a*) and the highest yellowness (b*). For ultrasonic treated samples, the a* and b* values tended to increase when the frequency intensity levels rose, which correlated with the values of color intensity (C*) and total different colors (∆E) in the samples. The viscosity, total soluble solids, pH, and total titratable acidity of the processed Ma-Kiang juice using heat and ultra-sonic processing at different frequency intensity levels showed no statistically significant differences when compared to the unprocessed samples. Samples processed with ultrasonication still retained high levels of bioactive compounds (total anthocyanins and total phenolic compounds) and antioxidant capacity (DPPH, FRAP, and ABTS•+ assays) compared to fresh samples, and they contained more than that processed by heat. The activities of polyphenol oxidase and peroxidase in the samples decreased after processing. Additionally, it was found that heat processing at a temperature of 80ºC for 2 min and ultrasonication at an intensity level of 80% could inhibit indicator microorganisms related to the sanitation and safe consumption of Ma-Kiang juice, bringing their numbers below the standards set by the Thai Community Product Standard (TCPS. 484/2014).

Conclusions : From this experimental research, it can be summarized that processing Ma-Kiang juice with ultra-sonication at kHz, with an intensity level of 80% for 20 minutes, was the most optimal condition. This method can better preserve various qualities and bioactive compounds, as well as the antioxidant efficiency of the product, compared to processing under other conditions. Additionally, it can be suggested that ultra-sonic processing was another option for fruit juice processing and can be commercially utilized. For future research, sensory evaluation may be required before the technology is further developed industrially, and the effects of ultra-sonic processing on the shelf life and other bioactive compounds in Ma-Kiang juice should also be studied.

References

AOAC. (2005). Official methods of analysis (18th ed.). Washington, DC: Association of Official Analytical Chemists.

Apichartsrangkoon, A., Srisajjalertwaja, S., Chaikham, P., & Hirun, S. (2013). Physical and chemical properties of Nam Prig Nhum, a Thai green chili paste, following ultra-high pressure and thermal processes. High Pressure Research: An International Journal, 31(1), 83-95.

Aslam, R., Alam, M. S., Ali, A., Tao, Y., & Manickam, S. (2023). A chemometric approach to evaluate the effects of probe-type ultrasonication on the enzyme inactivation and quality attributes of fresh amla juice. Ultrasonics Sonochemistry, 92, 106268.

Benzie, I. F. F., & Stain, J. J. (1996). The ferric reducing ability of plasma (FRAP) as a measure of antioxidant power; the FRAP assay. Analytical Biochemistry, 239, 70-76.

Bhat, R., & Goh, K. M. (2017). Sonication treatment convalesces the overall quality of hand pressed strawberry juice. Food Chemistry, 215, 470–476.

Cao, X., Cai, C., Wang, Y., & Zheng, X. (2018). The inactivation kinetics of polyphenol oxidase and peroxidase in bayberry juice during thermal and ultrasound treatments. Innovative Food Science and Emerging Technologies, 45, 169–178.

Chaikham, P. (2015). Comparison of high hydrostatic pressure and thermal processing on physicochemical and antioxidant properties of Maoberry (Antidesma thwaitesianum Müell. Arg.) juice. International Food Research Journal, 22(5), 1993-2001.

Chaikham, P., & Apichartsrangkoon, A. (2012). Comparison of dynamic viscoelastic and physicochemical properties of pressurised and pasteurised longan juices with xanthan addition. Food Chemistry, 134, 2194-2200.

Chaikham, P., & Prangthip, P. (2015). Alteration of antioxidative properties of longan flower-honey after high pressure, ultra-sonic and thermal processing. Food Bioscience, 10, 1-7.

Chaikham, P., Kemsawasd, V., & Apichartsrangkoon, A. (2016a). Effects of conventional and ultrasound treatments on physicochemical properties and antioxidant capacity of floral honeys from Northern Thailand. Food Bioscience, 15, 19-26.

Chaikham, P., Prangthip, P., & Seesuriyachan, P. (2016b). Ultra-sonication effects on quality attributes of maoberry (Antidesma bunius L.) juice. Food Science and Technology Research, 22(5), 647-654.

Cruz-Cansino, N., Pérez-Carrera, G., Zafra-Rojas, Q., Delgado-Olivares, L., Alanís-García, E., & Ramírez-Moreno, E. (2013). Ultrasound processing on green cactus pear (Opuntia ficus Indica) juice: Physical, microbiological and antioxidant properties. Journal of Food Processing and Technology, 4, 1-6.

Dabir, M. P., & Ananthanarayan, L. (2017). Effect of heat processing and ultrasonication treatment on custard apple peroxidase activity and vitamin C. International Journal of Food Engineering, 13, 99562367.

Dajanta, K., Chattong, U., & Rongkom, H. (2019). Color, pigments and antioxidant quality of red yeast rice (Angkak) fermented by various rice varieties. KKU Science Journal, 47(3), 468-477. (in Thai)

Engmann, F. N., Ma, Y., Tchabo, W., & Ma, H. (2014). Ultrasonication treatment effect on anthocyanins, color, microorganisms and enzyme inactivation of mulberry (Moraceae nigra) juice. Journal of Food Processing and Preservation, 39, 854-862.

Hasheminya, S. M., & Dehghannya, J. (2022). Non-thermal processing of black carrot juice using ultrasound: intensification of bioactive compounds and microbiological quality. International Journal of Food Science and Technology, 57, 5848–5858.

Iqbal, A., Murtaza, A., Marszalek, K., Iqbal, M. A., Chughtai, M. F., Hu, W., Barba, F. J., Bi, J., Liu, X., & Xu, X. (2020). Inactivation and structural changes of polyphenol oxidase in quince (Cydonia oblonga Miller) juice subjected to ultrasonic treatment. Journal of the Science of Food and Agriculture, 100, 2065–2073.

Kerdsup, P., Hattayapichat, P., Silva, J. L., & Tantratian, S. (2022). Survival of potential probiotic isolated from fermented tea leaf and encapsulated in multilayer beads stored in makiang (Cleistocalyx nervosum var. paniala) juice. Food Bioscience, 50, 102015.

Kumar V., & Banker G. S. (2005). Maillard reactions in chemistry, food and health (pp. 20-27). Elsevier; Amsterdam, The Netherlands.

Kwaw, E., Ma, Y., Tchaboa, W., Sackey, A. S., Apaliya, M. T., Xiao, L., Wu, M., & Sarpong, F. (2018). Ultrasonication effects on the phytochemical, volatile and sensorial characteristics of lactic acid fermented mulberry juice. Food Bioscience, 24, 17–25.

Lepaus, B. M., Valiati, B. S., Machado, B. G., Domingos, M. M., Silva, M. N., Faria-Silva, L., Bernardes, P. C., da Silva Oliveira, D., & de Sao Jose, J. F. B. (2023). Impact of ultrasound processing on the nutritional components of fruit and vegetable juices. Trends in Food Science & Technology, 138, 752–765.

Liu, M., Li, J., Zong, W., Sun, W., Mo, W., & Li, S. (2022). Comparison of calcium and ultrasonic treatment on fruit firmness, pectin composition and cell wall-related enzymes of postharvest apricot during storage. Journal of Food Science and Technology, 59, 1588–1597.

Mohideen, F. W., Solval, K. M., Li, J., Zhang, J., Chouljenko, A., Chotiko, A., Prudente, A. D., Bankston, J. D., & Sathivel, S. (2015). Effect of continuous ultra-sonication on microbial counts and physico-chemical properties of blueberry (Vaccinium corymbosum) juice. LWT - Food Science and Technology, 60, 563-570.

Nadeem, M., Ranjha, M. M. A. N., Ameer, K., Ainee, A., Yasmin, Z., Javaria, S., & Teferra, T. F. (2022). Effect of sonication on the functional properties of different citrus fruit juices. International Journal of Fruit Science, 22, 568-580.

Nantacharoen, W., Baek, S. J., Plaingam, W., Charoenkiatkul, S., Tencomnao, T., & Sukprasansap, M. (2022). Cleistocalyx nervosum var. paniala berry promotes antioxidant response and suppresses glutamate-induced cell death via SIRT1/Nrf2 survival pathway in hippocampal HT22 neuronal cells. Molecules, 27(18), 5813.

Oladunjoye, A. O., & Awani-Aguma, E. U. (2023). Effect of thermosonication on physicochemical, bioactive, sensory and microbiological qualities of African mango fruit (Irvingia gabonensis) juice. Measurement: Food, 11, 100103.

Patthamakanokporn, O., Puwastien, P., Nitithamyong, A., & Sirichakwal, P. P. (2008). Changes of antioxidant activity and total phenolic compounds during storage of selected fruits. Journal of Food Composition and Analysis, 21, 241–248.

Phupinyokul, M. (2016). Acceptance and nutritive values of makiang juice and the analyses of antioxidants makiang fruits (Cleistocalyx nervosum var paniala). Agricultural Science Journal, 47(1), 103–113. (in Thai)

Piecko, J., Mieszczakowska, M., Celejewska, K., & Szwejda-Grzybowska, J. (2024). Impact of ultrasound pretreatment on juice yield and bioactive content in juice produced from selected berries fruit. Foods, 13, 1231.

Prasanth, M. I., Brimson, J. M., Chuchawankul, S., Sukprasansap, M., & Tencomnao, T. (2019). Antiaging, stress resistance, and neuroprotective efficacies of Cleistocalyx nerovosum var paniala fruit extracts using Caenorhabditis elegans model. Oxidative Medicine and Cellular Longevity, 2019, 7024785.

Radziejewska-Kubzdela, E., Szwengiel, A., Ratajkiewicz, H., & Nowak, K. (2020). Effect of ultrasound, heating and enzymatic pretreatment on bioactive compounds in juice from Berberis amurensis Rupr. Ultrasonics Sonochemistry, 63, 104971.

Ravikumar, M. (2017). Ultrasonication: An advanced technology for food preservation. International Journal of Pure & Applied Bioscience, 5, 363–371.

Roobab, U., Abida, A., Madni, G. M., Ranjha, M. M. A. N., Zeng, X.-A., Khaneghah, A. M., & Aadil, R. M. (2023). An updated overview of ultrasound-based interventions on bioactive compounds and quality of fruit juices. Journal of Agriculture and Food Research, 14, 100864.

Shahid, M. B., Nadeem, M., Qureshi, T. M., Shahid, M. A., Asif, A., Balal, R. M., Ahmed, S., Rukh, L., Nawaz, A., & Ahmad, N. (2025). Comparison of thermo-sonication and conventional pasteurization on the quality attributes of some selected citrus fruit juices. Measurement: Food, 17, 100212.

Sudsanor, P., Chaikham, P., Thanaboonrongkom, S., & Dajanta, K. (2023). Physicochemical and antioxidative properties of Barringtonia acutangula leaf tea produced by hot-air drying and conventional roasting. Burapha Science Journal, 28(3), 1854-1870. (in Thai)

Thai Industrial Standards Institute. (2014). Thai Community Product Standard : Makiang Drink (TCPS. 484/2014). Ministry of Industry, Thailand.

Thuschana, W., Thumvijit, T., Chansakaow, S., Ruamrungsri, S., & Wongpoomchai, R. (2020). Chemical constituents and antioxidant activities of Cleistocalyx Nervosum fruits in in vitro and in vivo models. Thai Journal of Toxicology, 27(2), 194.

US Food and Drug Administration. (2001). Bacteriological analytical manual (BAM). Department of Health and Human Services, New Hampshire Avenue, Washington DC.

Xu, K., Fan, G., Wu, C., Suo, A., & Wu, Z. (2022). Preparation of anthocyanin-rich mulberry juice by microwave-ultrasonic combined pretreatment. Food Science and Biotechnology, 31, 1571–1581.

Zainol, M. K., Adb-Hamid, A., Yusof, S., & Muse, R. (2003). Antioxidative activity and total phenolic compounds of leaf, root and petiole of four accessions of Centella asiatica (L.) Urban. Food Chemistry, 81, 575–581.

Zhu, D., Zhang, Y., Kou, C., Xi, P., & Liu, H. (2022). Ultrasonic and other sterilization methods on nutrition and flavor of cloudy apple juice. Ultrasonics Sonochemistry, 84, 105975.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Faculty of Science, Burapha University

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Burapha Science Journal is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International (CC BY-NC-ND 4.0) licence, unless otherwise stated. Please read our Policies page for more information