Qualities of Mixed Vegetables/Fruit Juice from Fresh-Cut Salad Waste under High-Pressure Processing

Keywords:

high-pressure technology , non-thermal processing , mixed vegetable and fruit juice , physicochemical properties , microbiologyAbstract

Background and Objectives : High pressure processing (HPP) is a non-thermal food processing technology that has emerged as innovative methods capable of microbial inactivation and enzyme inhibition while preserving nutritional value, flavor compounds, and bioactive substances. HHP is a favorable application in food industry including juices, jams, and other fruit products. The core benefits of HHP processing are the reduction or significant elimination of heating, avoiding the degradation of the food component from heat. In addition, there is a large amount of fresh-cut salad waste after the cutting process that cannot be sold due to their unappetizing characteristics but have nutrition values and bioactive substances such as antioxidants, etc., with no difference from fresh salad vegetables. Therefore, food processing is required to change this appearance from food waste to juice but still preserve the nutrient value of the bioactive compounds as much as possible. This study aimed to investigate the effects of high-pressure processing (HPP) at various levels of pressure and time on the physical properties, chemical properties, and microbials of a mixed vegetable and fruit juice product.

Methodology : Three types of vegetables (such as Green oak vegetables, red oak vegetables, and mini cos lettuce) from fresh-cut salad waste) and fruits, including red grapes, red apples, and lemons, were extracted using a cold press processor and then mixed. The proportion of mixed vegetables (Green oak vegetables, red oak vegetables, and mini cos lettuce in the proportion 45:45:10 % by weight, respective), red grapes, red apples, and lemons were 59.58, 23.57, 14.85 and 2 % by weight, respectively. Mixed vegetables and fruit juice were packed in polyethylene terephthalate bottle (PET) for 150 ml. Then, mixed vegetables/fruit juice were examined as pressure levels of 300, 400, and 500 MPa applied for durations of 3, 6, and 9 minutes. All Mixed vegetables and fruit juice samples were physical, chemical and microbiology analyzed such as color, turbidity, total soluble solids content, pH value, total phenolic contents, antioxidant activity by DPPH and FRAP assays, total microbial and yeast and mold contents.

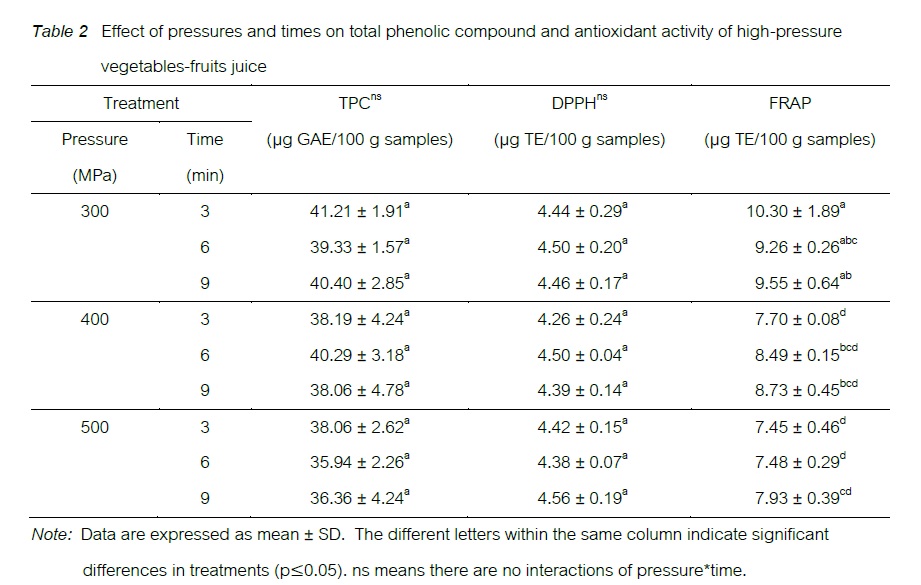

Main Results : Results demonstrated that pressure and time had significant interactive effects on redness (a*) and total microbial count (p≤0.05). Furthermore, pressure levels significantly influenced brightness (L*), redness (a*), yellowness (b*), pH, and antioxidant activity as measured by the Ferric Reducing Antioxidant Power (FRAP) assay (p≤0.05). Mixed vegetables and fruit juice under pressure at 500 MPa for 5 min was increased in a* value (a* = -0.50, p≤0.05). However, pressure levels and time did not affect turbidity and total soluble solids content (TSS) of mixed vegetables and fruit juice samples (p>0.05). Notably, increasing pressure levels correlated with decreased FRAP antioxidant activity (p≤0.05). FRAP contents of mixed vegetables and fruit juice under pressure at 500 MPa with duration between 3 and 9 min ranged from 7.45 to 7.93 µg TE/100 g sample. Pressure levels, times and interaction between pressure levels and time (P*T) did not affect total phenolic contents and antioxidant activity by DPPH assays of mixed vegetables and fruit juice (p>0.05). Total phenolic contents and antioxidant activity by DPPH assays of mixed vegetables and fruit juice ranged from 35.94-41.21 µg GAE/100 g samples and 4.26-4.56 µg TE/100 g samples, respectively. Processing time significantly affected only brightness and pH (p≤0.05). The pH values of mixed vegetables and fruit juice samples under HPP process at 300 MPa for 3-6 min were ranged between 3.83 and 3.84. When pressure level and time increased, total plate count decreased (p≤0.05). Total microbial contents of mixed vegetables and fruit juices under pressure level more than 300 MPa for 3-9 min had ranged from 3.33 to 6.00 CFU/ml. While pressure, time, and their interaction did not significantly impact yeast and mold counts in the juice samples (p>0.05). The results exhibited that total yeast and molds of mixed vegetables and fruit juices under HPP were lower than mixed vegetables and fruit juices with untreated HPP. All treated samples exhibited microbial, yeast, and mold counts below the general criteria and limits set for high-pressure pasteurized acidic products (pH ≤ 4.64). These findings align with the Thai Food and Drug Administration’s (2019) guidelines, which recommend pressures of at least 400 MPa for 1-20 minutes for such products.

Conclusions : High-pressure processing of mixed vegetable and fruit juice at 400 MPa for 6 minutes emerges as a promising non-thermal treatment with potential for industrial application. This HPP condition exhibits a higher of total phenolic contents, and antioxidant activity by DPPH and FRAP assays in mixed vegetables and fruit juices from fresh-cut salad waste. Moreover, microbial, yeast, and mold counts align with the Food and Drug Administration’s (2019) guidelines with an appropriate cost. This method not only ensures microbiological safety and quality but also presents an opportunity to add value to by-products from the fresh-cut produce industry or substandard vegetables, transforming them into nutritious health beverages.

References

AOAC. (2000). Official Methods of Analysis of the Association of Official Analytical Chemists, (17thed.). Washington D.C.

Food and Drug Administration. (2019). General criteria and product scope for using the high pressure pasteurization process (High-Pressure Processing (HPP)). (pp. 1-6). (in Thai)

Fuangpaiboon, N., Srijesdaruk, V., & Kijroongrojana, K. (2024). The effects of mixed proteins on the physical and rheological properties and the sensory qualities of a newly formulated plant-based soup for elderly consumers. Asia-Pacific Journal of Science and Technology, 29(1), 1-10.

Heremans, K. (1995). High-pressure effect on biomolecules. In D.A. Ledward, D.E. Johnston, R.G. Earnshaw, & A.P.M. Hastings. (Eds.), High Pressure Processing of Foods. (pp. 81-97). Nottingham University Press: Nottingham.

Jayachandran, L. E., Chakraborty, S., & Rao, P. R. (2015). Effect of high pressure processing on physicochemical properties and bioactive compounds in litchi based mixed fruit beverage. Innovative Food Science and Emerging Technologies, 28, 1-9.

Jiang, Y., & Li, Y. (2001). Effects of chitosan coating on postharvest life and quality of longan fruit. Food Chemistry, 73, 139-143.

Koo, A., Chew, D.X., Ghate, V., & Zhou, W. (2023). Residual polyphenol oxidase and peroxidase activities in high pressure processed bok choy (Brassica rapa subsp. chinensis) juice did not accelerate nutrient degradation during storage. Innovative Food Science and Emerging Technologies, 84, 1-9.

Li, Y., & Padilla-Zakour, O. I. (2024). Evaluation of pulsed electric field and high-pressure processing on the overall quality of refrigerated Concord grape juice. LWT - Food Science and Technology, 198, 116002.

Oey, I., Lille, M., Loey, A.V., & Hendrickx, M. (2008). Effect of highpressure processing on colour, texture and flavour of fruit- and vegetable-based food products: a review. Trends in Food Science & Technology, 19, 320-328.

Petrus, R., Churey, J., & Worobo, R. (2020). Searching for high pressure processing parameters for Escherichia coli O157:H7, Salmonella enterica and Listeria monocytogenes reduction in Concord grape juice. British Food Journal, 122(1), 170-180.

Phungamngoen, C., Eadmusik, S., & Suwan T. (2018). Influence of sterilize condition and storage time of canned bamboo shoot in Yanang juice. Italian Journal of Food Science, 30(5), 24-29.

Rios-Corripio, G., Welti-Chanes, J., Rodríguez-Martínez, V., & Guerrero-Beltr´an, J. ´A. (2024). High hydrostatic pressure processing of fresh juice and a fermented beverage of black cherry (Prunus serotina). Journal of Agriculture and Food Research, 15, 100937.

Sanguansil, S., Boonprakob, U., & Thaipong, K. (2011). Antioxidant Activity, Phenolics, Flavonoids and Fruit Quality of Dessert-type Guava. Agricultural Science Journal, 42 (Suppl), 579-582.

Sawaengpon, S. (2011). The relationship between quality changes and respiration rate of fresh-cut vegetable salad stored under modified atmosphere package. M.Sc. Thesis. Suranaree University of Technology.

Stinco, C. M., Szczepańska, J., Marszałek, K., Pinto, C. A., Inácio, R. S., Mapelli-Brahm, P., Barba, F. J., Lorenzo, J., M., Saraiva, J. A., & Meléndez-Martínez, A. J. (2019). Effect of high-pressure processing on carotenoids profile, colour, microbial and enzymatic stability of cloudy carrot juice. Food Chemistry, 299, 125112.

Szczepa´nska, J., Skąpska, S., Lorenzo, J. M., & Marszałek, K. (2021). The influence of static and multi-pulsed pressure processing on the enzymatic and physico-chemical quality, and antioxidant potential of carrot juice during refrigerated storage. Food and Bioprocess Technology, 14, 52–64.

Tangwongchai, R., Ledward, D.A., & Ames, J.M. (2000). Effect of high pressure treatment on the texture of cherry tomatoes. Journal of Agricultural and Food Chemistry, 48(5), 1434-1441.

Tangwongchai, R., & Attapolpaisarn, C. (2010). Effect of high pressure and temperature treatment on PME activity in cloudy fruit juice. Food Journal, 40(2), 42-46. (in Thai)

Thai Community Product Standard. (2014). TCPS 1307/2014 Mix Fruits Syrup. Thai Industrial Standards Institute. (in Thai)

Xia, Q., Liu, C., Cao, Y., Zhao, Y., Lu, S., Wu, D., Aniya, & Guan, R. (2023). Improving quality of sea buckthorn juice by high-pressure processing. LWT - Food Science and Technology, 185, 115149.

Yuan, B., Danao, M.C., Lu, M., Weier, S.A., & Stratton, J.S. (2018). High pressure processing (HPP) of aronia berry puree: Pilot scale processing. Innovative Food Science and Emerging Technologies, 47, 241-248.

Zou, W., Niu, H., Yi, J., & Zhou, L. (2024). Passion fruit juicing with or without seeds treated by high-pressure processing and thermal pasteurization: Effects on the storage stability of enzymes and quality properties. Innovative Food Science and Emerging Technologies, 91, 103554.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Faculty of Science, Burapha University

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Burapha Science Journal is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International (CC BY-NC-ND 4.0) licence, unless otherwise stated. Please read our Policies page for more information